saw handle

prototyping process

The handle project had a goal to show the prototyping process from start to finish. Starting at foam model development, to hard models, to resin casted prototypes. This project lasted one and a half semesters, during my final year at Dawson College Industrial Design. I was assigned to redesign an all purpose push-pull saw handle.

phase one: foam model concept development

phase two: basswood hard model

phase three: making the final prototype

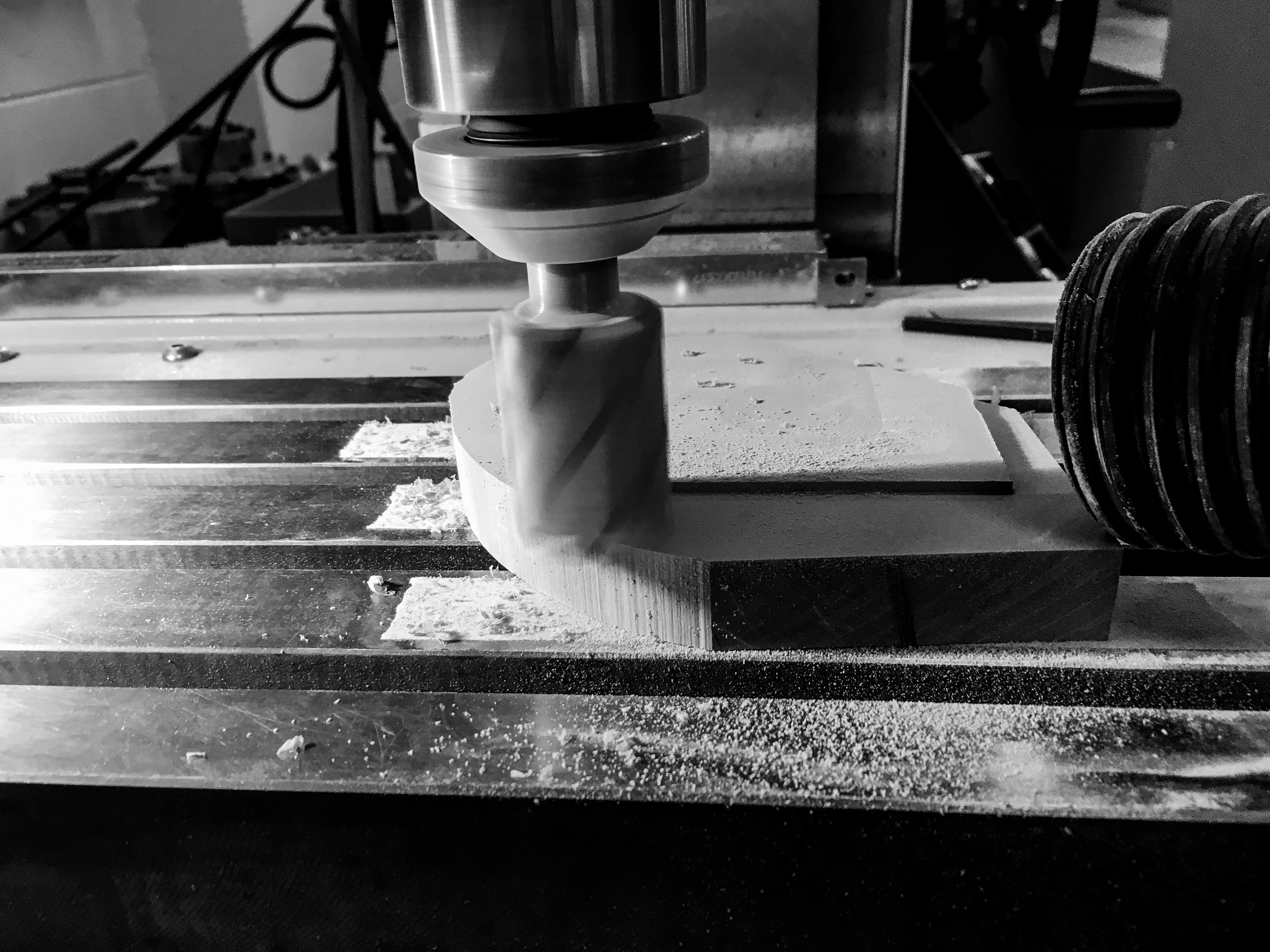

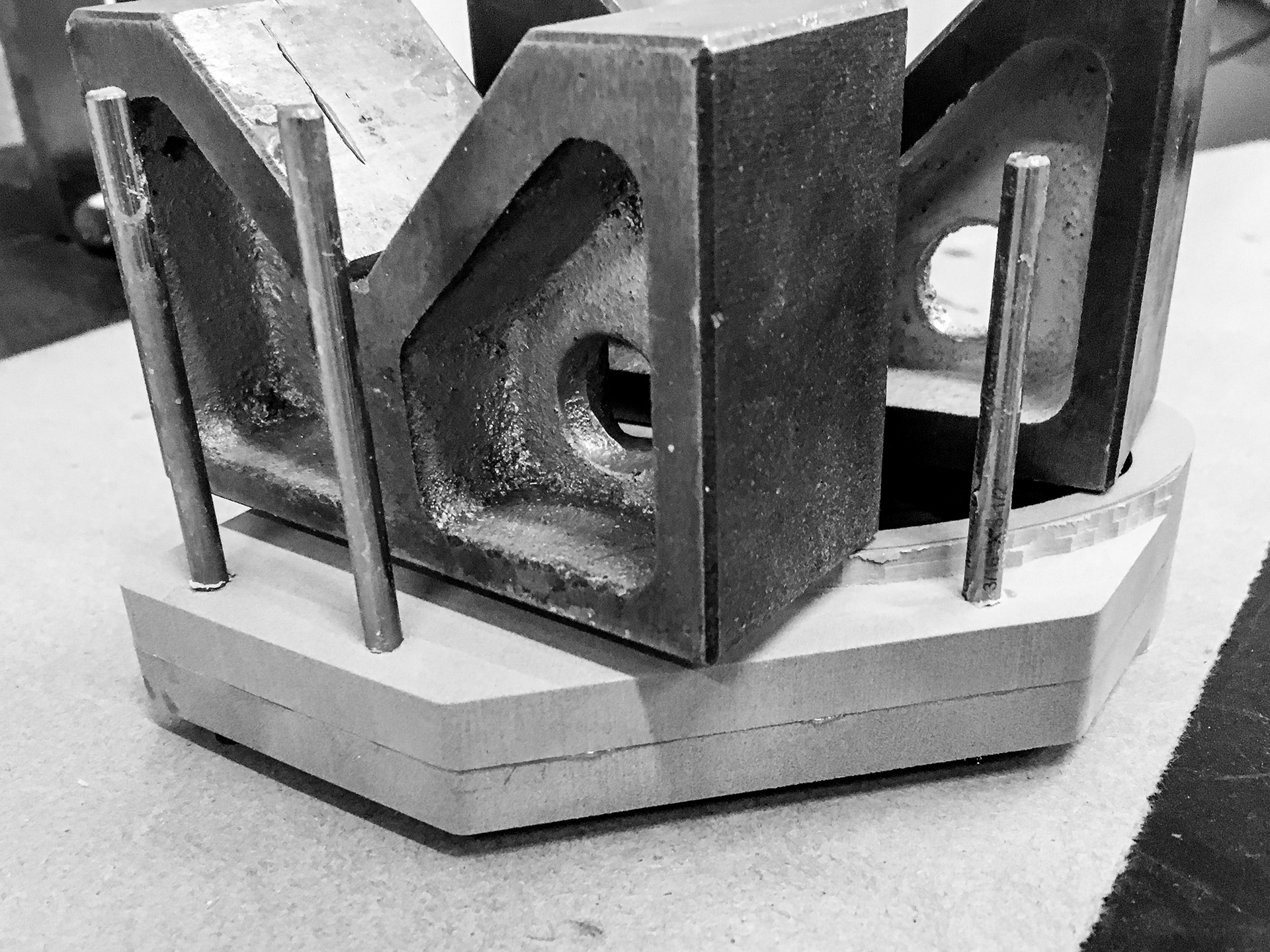

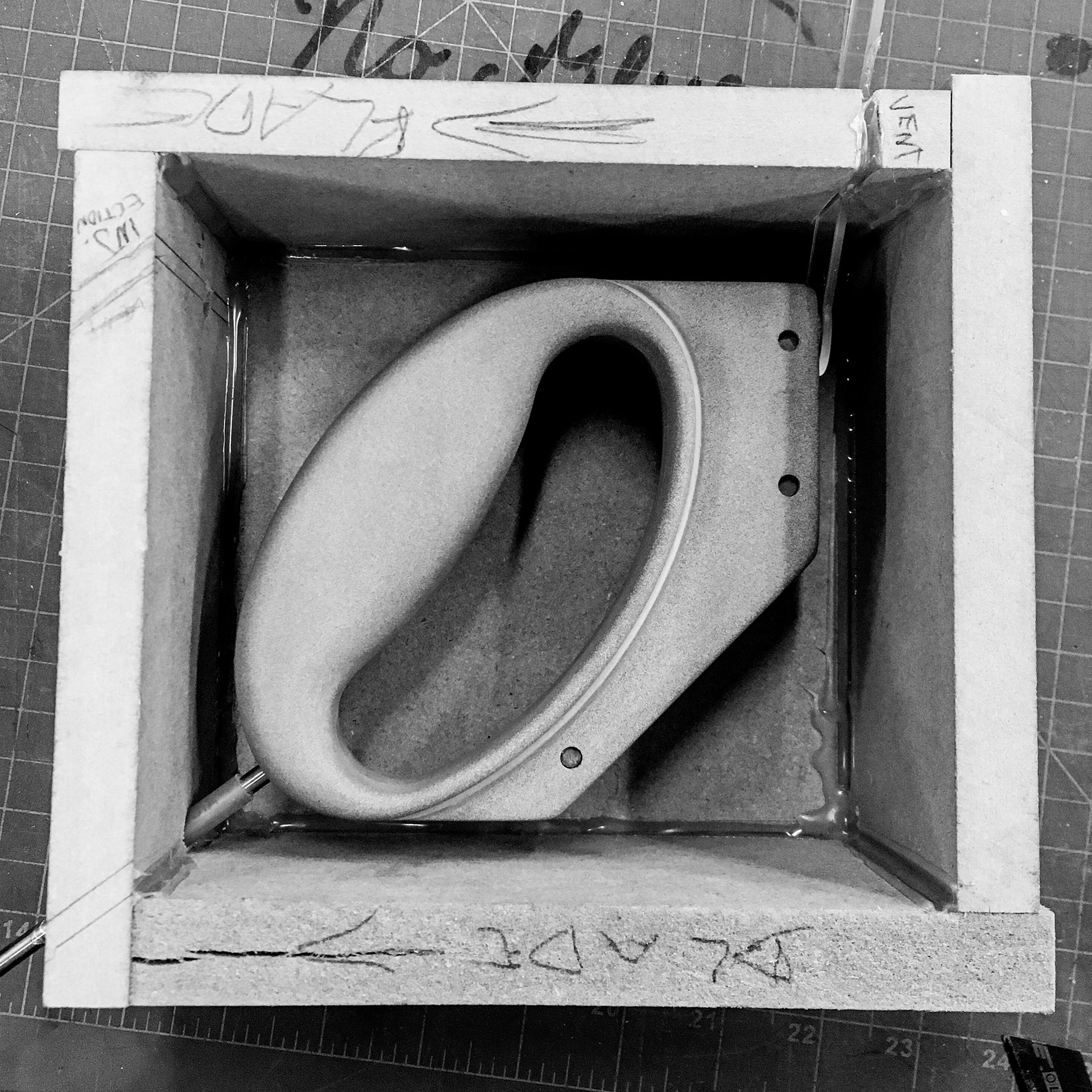

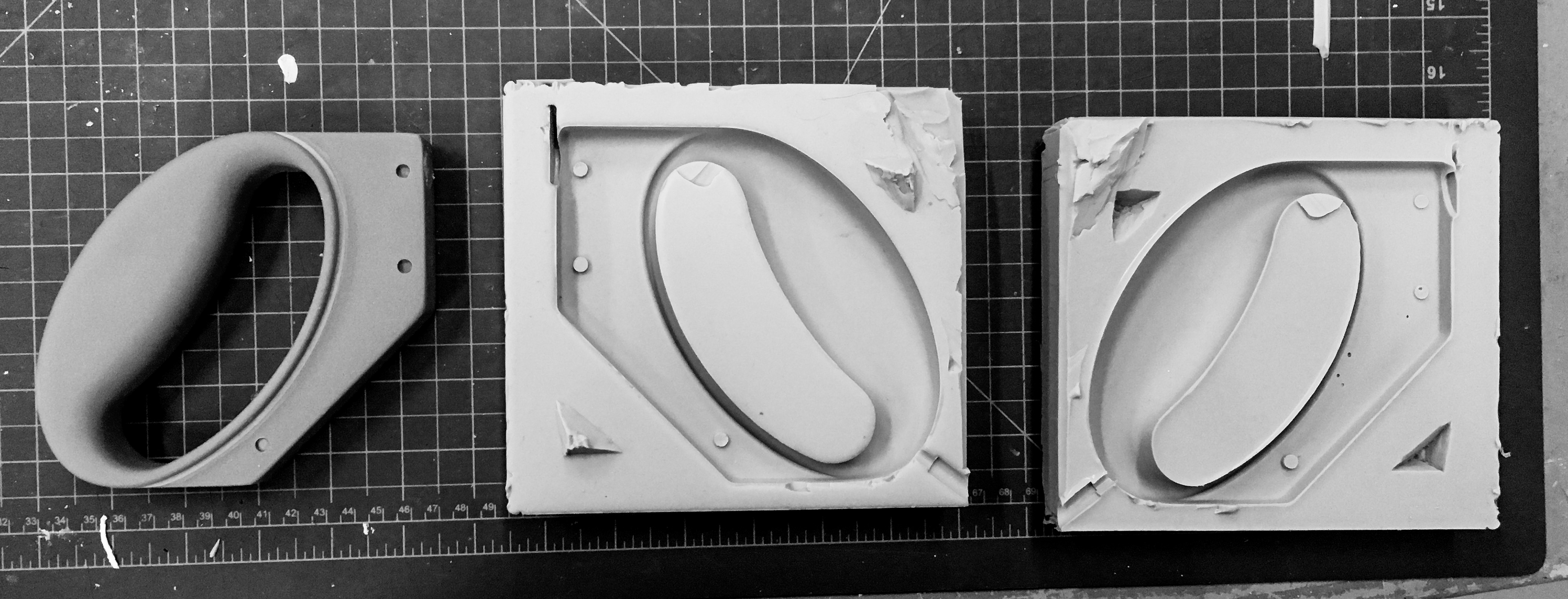

the process starts by making a renshape master model. Then, a two-part mold is cast out of silicone around the master. This mold can then be used to cast urethane handles repeatedly.

two blocks of renshape

styrene template

rough trimming

milling to thickness

router profile with template

milling step down

glueing halves together

rounding edges

verified with profile templates

body filler for inside fillet

finishing body filler

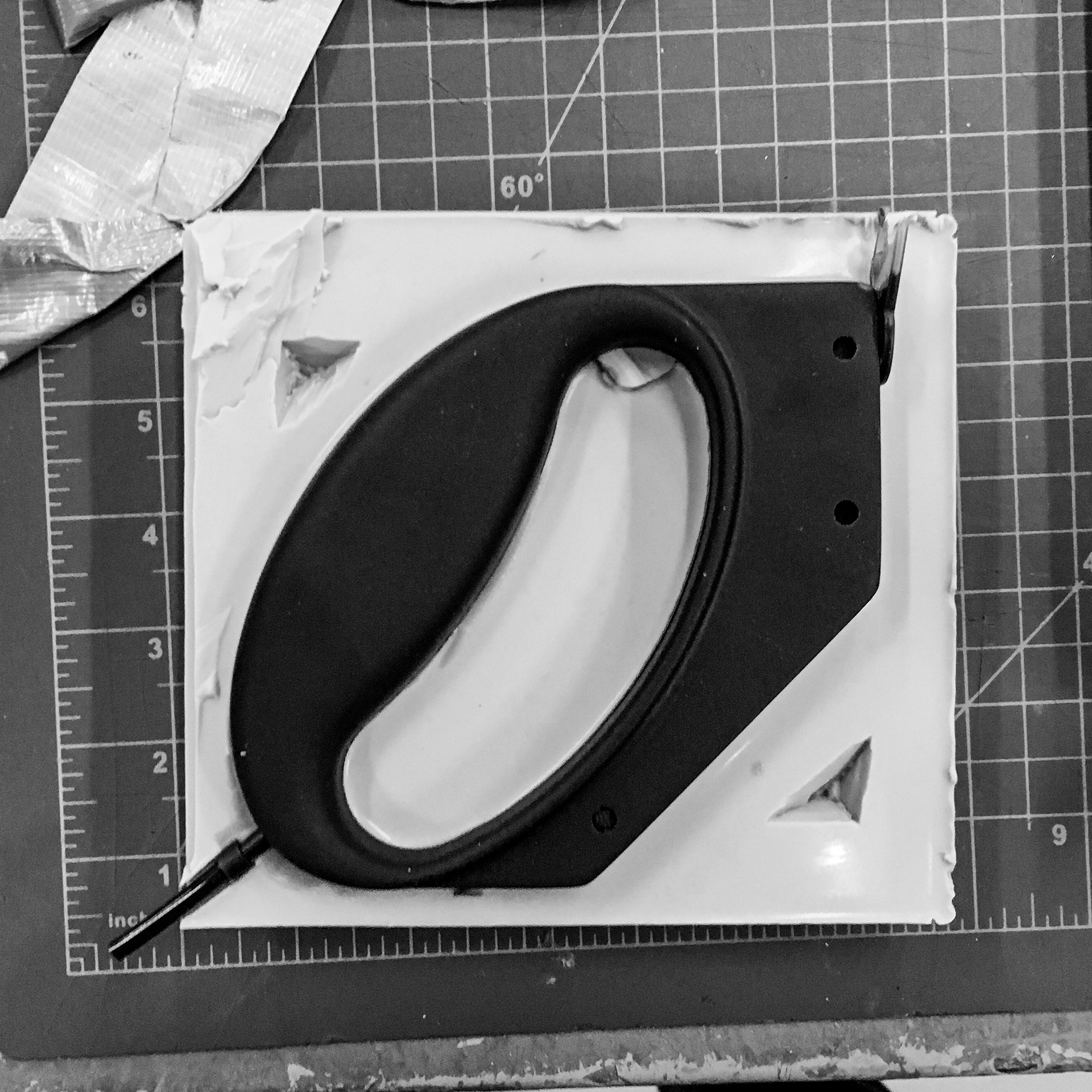

casting box

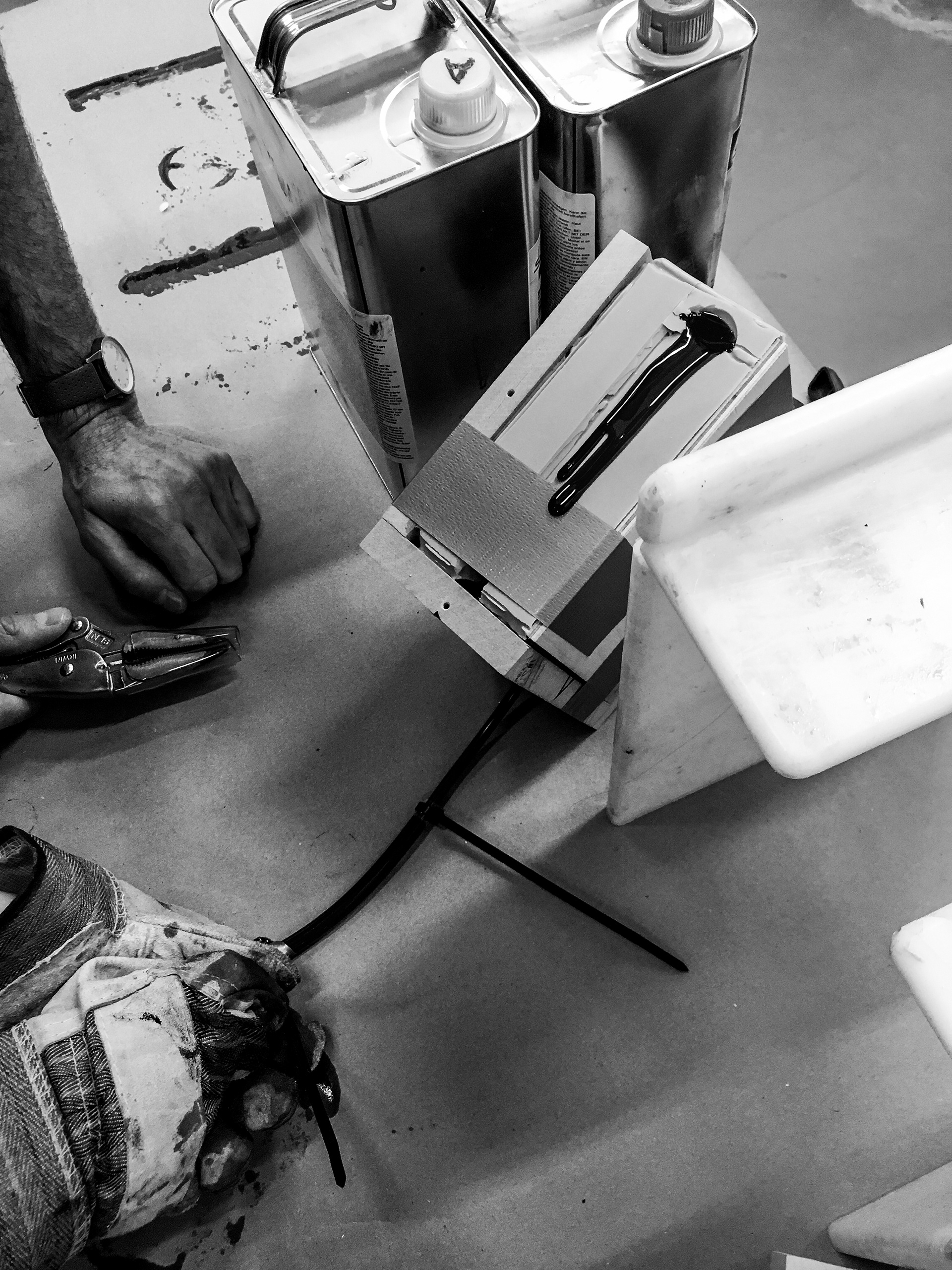

measuring silicone

silicone casting

demolding renshape

preparing for urethane casting

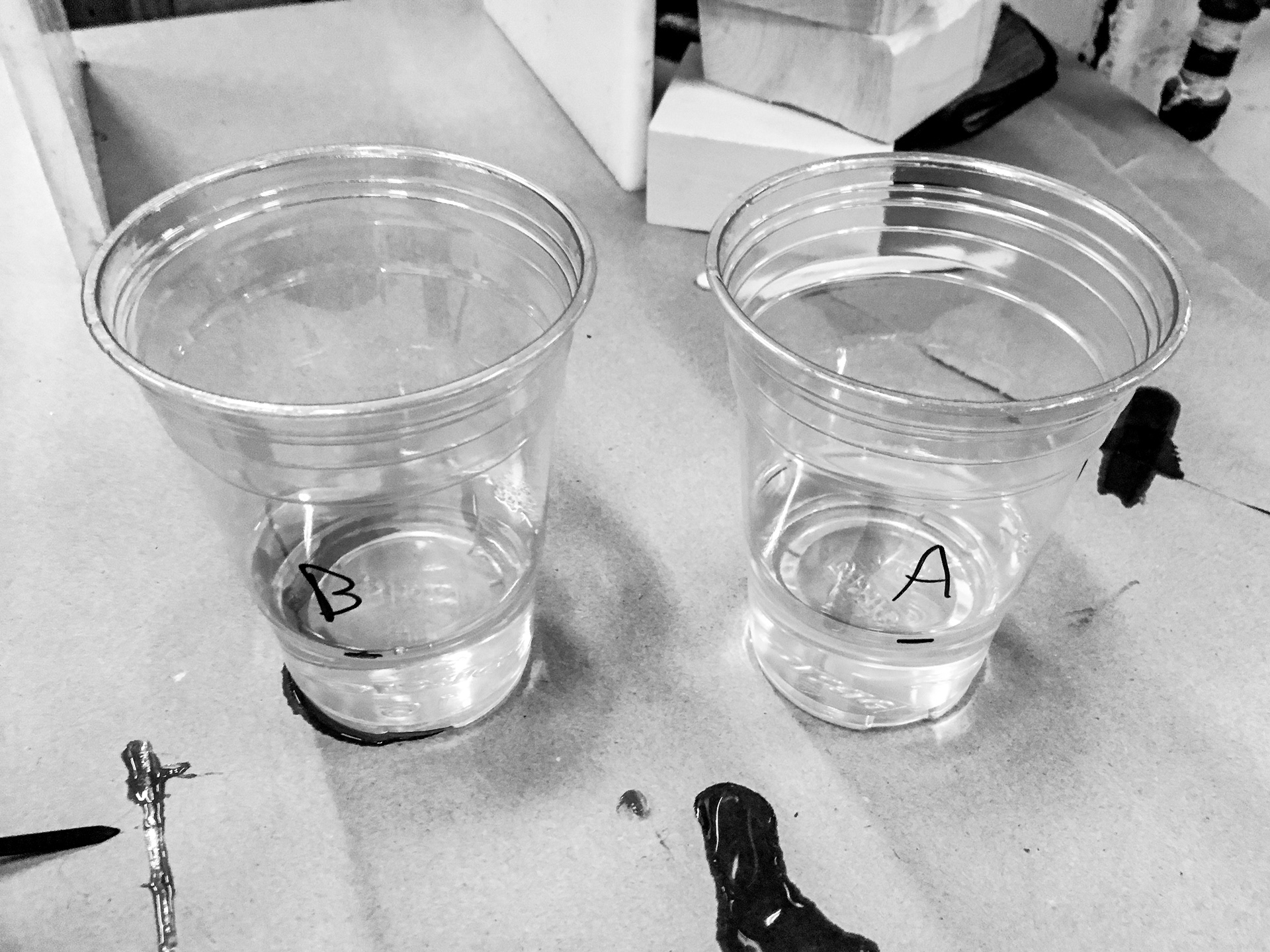

part A and B of resin

mixing in the dye

injecting resin

demolding casted handle

drilling fastener holes

counter-boring fastener holes

creating blade slot

final three handles